- Introduction to laser cleaning technology

- Comparison of laser cleaning with traditional cleaning methods

- Safety considerations when using laser cleaning for medical equipment

- Challenges and limitations of using laser cleaning for medical equipment

- Regulatory requirements for cleaning medical equipment

- Impact of contaminants on the performance of medical equipment

- Case studies of improved patient satisfaction with laser-cleaned medical equipment

- Comparison of laser cleaning with traditional cleaning methods

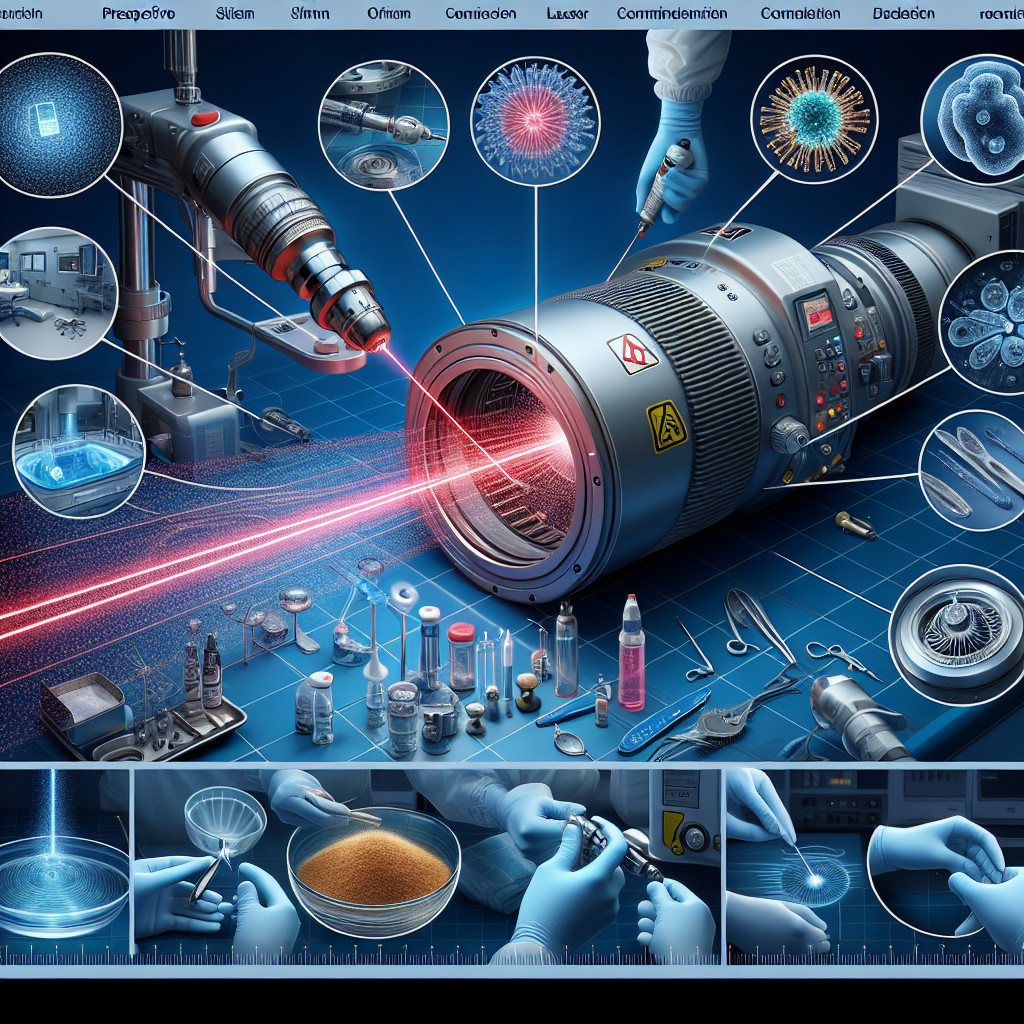

Introduction to laser cleaning technology

How Laser Cleaning Works

During laser cleaning, a laser beam is directed at the surface of the material to be cleaned. The energy from the laser beam vaporizes the contaminants, leaving behind a clean surface. This process is non-abrasive and does not damage the underlying material, making it ideal for delicate surfaces.

Benefits of Laser Cleaning

There are many benefits to using laser cleaning technology. Some of the key advantages include:

| Advantages | Description |

|---|---|

| Non-abrasive | Laser cleaning does not damage the underlying material. |

| Environmentally friendly | Does not require the use of chemicals or solvents. |

| Highly precise | Can target specific areas without affecting surrounding areas. |

| Efficient | Removes contaminants quickly and effectively. |

Applications of Laser Cleaning

Laser cleaning technology is used in a wide range of industries for various applications. Some common uses include:

| Industry | Application |

|---|---|

| Manufacturing | Removing rust and paint from metal surfaces. |

| Aerospace | Cleaning turbine blades and engine components. |

| Automotive | Removing coatings from car parts. |

Conclusion

Laser cleaning technology is a versatile and efficient method of removing contaminants from surfaces. Its non-abrasive nature and precision make it a valuable tool for a wide range of industries.

#laser #cleaning #technology #manufacturing #aerospace #automotive

słowa kluczowe: laser, cleaning, technology, contaminants, coatings, oxides, surfaces, high-powered, beam, efficient, non-abrasive, industries, manufacturing, automotive, aerospace, vaporizes, environmentally friendly, precise, applications.

frazy kluczowe: laser cleaning technology benefits, laser cleaning process, laser cleaning applications, laser cleaning advantages, laser cleaning industries.

Comparison of laser cleaning with traditional cleaning methods

One of the key advantages of laser cleaning is its ability to remove contaminants with precision and without damaging the underlying surface. Traditional cleaning methods, on the other hand, can be abrasive and may cause wear and tear on the surface being cleaned. Laser cleaning is particularly effective for removing rust, paint, and other stubborn contaminants from metal surfaces.

Efficiency:

Laser cleaning is a faster and more efficient process compared to traditional methods. It requires less manual labor and can be automated for continuous cleaning operations. Traditional methods such as scrubbing or sandblasting can be time-consuming and labor-intensive, especially for large surfaces or complex geometries.

Cost:

While the initial investment in laser cleaning equipment may be higher than traditional cleaning methods, the long-term cost savings can be significant. Laser cleaning requires less consumables and produces less waste compared to traditional methods. Additionally, the efficiency of laser cleaning can result in reduced downtime and increased productivity.

Environmental impact:

Laser cleaning is a more environmentally friendly option compared to traditional cleaning methods. It does not require the use of harsh chemicals or solvents, reducing the risk of pollution and harm to the environment. Laser cleaning also produces less waste and emissions, making it a sustainable choice for industries looking to reduce their carbon footprint.

In conclusion, laser cleaning offers several advantages over traditional cleaning methods in terms of effectiveness, efficiency, cost, and environmental impact. While the initial investment may be higher, the long-term benefits make it a worthwhile investment for industries looking to improve their cleaning processes.

Keywords: laser cleaning, traditional cleaning methods, effectiveness, efficiency, cost, environmental impact

Long-tail phrases: , advantages of laser cleaning, environmentally friendly cleaning options

#laser #cleaning #traditional #methods #efficiency #environmental #impact #cost #advantages #technology #manufacturing #healthcare #rust #paint #abrasive #precision #waste #pollution #sustainable #investment #productivity #carbon #footprint #industries #processes #benefits #maintenance #automated #contaminants #surface #equipment #solvents #emissions #scrubbing #sandblasting #chemicals #wear #tear #downtime #geometries #consumables #waste #pollution #harm #sustainable #carbon #footprint #improve #processes.

Safety considerations when using laser cleaning for medical equipment

Here are some important safety considerations to keep in mind:

1. Eye protection: Laser cleaning produces intense light that can cause damage to the eyes if proper eye protection is not worn. It is important to ensure that all personnel in the vicinity of the laser cleaning process wear appropriate eye protection to prevent any potential eye injuries.

2. Skin protection: In addition to eye protection, it is also important to protect the skin from exposure to the laser beam. Direct contact with the laser beam can cause burns and other skin injuries, so it is important to wear appropriate protective clothing when using laser cleaning equipment.

3. Ventilation: Laser cleaning produces fumes and particles that can be harmful if inhaled. It is important to ensure that the area where laser cleaning is taking place is well-ventilated to prevent any potential respiratory issues.

4. Training: Proper training is essential when using laser cleaning equipment. All personnel involved in the laser cleaning process should be trained on how to safely operate the equipment and what safety precautions to take to prevent any accidents.

5. Maintenance: Regular maintenance of the laser cleaning equipment is important to ensure that it is functioning properly and safely. Any malfunctions or issues with the equipment should be addressed immediately to prevent any potential safety hazards.

In conclusion, laser cleaning can be a highly effective method for cleaning medical equipment, but it is important to prioritize safety when using this technology. By following proper safety protocols and taking necessary precautions, the risk of accidents and injuries can be minimized.

#safetyconsiderations #laser cleaning #medicalequipment #eyeprotection #skinprotection #ventilation #training #maintenance

frazy kluczowe:

– Safety precautions for laser cleaning in medical settings

– Importance of eye protection in laser cleaning

– Preventing skin injuries during laser cleaning

– Ensuring proper ventilation during laser cleaning

– Training requirements for laser cleaning operators

– Importance of maintenance in laser cleaning equipment.

Challenges and limitations of using laser cleaning for medical equipment

Challenges:

– **Safety concerns**: Laser cleaning can pose a risk to both the operator and the equipment if not used properly. Protective gear and training are essential to prevent accidents.

– **Limited effectiveness on certain materials**: Some materials may not respond well to laser cleaning, leading to incomplete removal of contaminants.

– **Cost**: The initial investment in laser cleaning equipment can be high, making it a less accessible option for smaller medical facilities.

– **Regulatory compliance**: Medical equipment must meet strict cleanliness standards, and it can be challenging to ensure that laser cleaning meets these requirements.

Limitations:

– **Surface damage**: Laser cleaning can potentially damage delicate medical equipment if not used correctly.

– **Limited reach**: Laser beams have a limited reach, making it difficult to clean hard-to-reach areas on complex medical devices.

– **Time-consuming**: Laser cleaning can be a time-consuming process, especially for large or intricate equipment.

– **Maintenance**: Laser cleaning equipment requires regular maintenance to ensure optimal performance, adding to the overall cost.

In conclusion, while laser cleaning offers many benefits for cleaning medical equipment, it also comes with its own set of challenges and limitations. It is important for medical facilities to weigh the pros and cons before implementing this technology in their cleaning processes.

#laser #cleaning #medical #equipment #challenges #limitations

#safetyconcerns #cost #regulatorycompliance #surfacedamage #timemanagement #maintenanceissues

Regulatory requirements for cleaning medical equipment

Regulatory bodies

There are several regulatory bodies that set standards for cleaning medical equipment, including the Food and Drug Administration (FDA), the Centers for Disease Control and Prevention (CDC), and the Occupational Safety and Health Administration (OSHA). These organizations provide guidelines and regulations that healthcare facilities must follow to ensure that medical equipment is properly cleaned and maintained.

Guidelines for cleaning medical equipment

- Use appropriate cleaning agents and disinfectants

- Follow manufacturer’s instructions for cleaning and maintenance

- Implement proper cleaning protocols and procedures

- Regularly inspect and monitor equipment for cleanliness

- Train staff on proper cleaning techniques and procedures

Consequences of non-compliance

Failure to comply with regulatory requirements for cleaning medical equipment can have serious consequences, including the spread of infections, increased risk of healthcare-associated infections, and potential legal repercussions. Healthcare facilities that do not adhere to cleaning standards may face fines, lawsuits, and damage to their reputation.

Conclusion

Ensuring that medical equipment is properly cleaned and maintained is essential to providing quality healthcare and preventing the spread of infections. Healthcare facilities must adhere to regulatory requirements for cleaning medical equipment to maintain a clean and safe environment for patients and healthcare workers.

#RegulatoryRequirements #CleaningMedicalEquipment #HealthcareStandards

#PreventingInfections #ProperCleaningTechniques #HealthcareSafety

Impact of contaminants on the performance of medical equipment

Types of contaminants

Contaminants come in many forms, including:

- Dust and dirt

- Fluids and liquids

- Bacteria and germs

- Chemicals and solvents

Each type of contaminant poses its own unique challenges when it comes to maintaining the performance of medical equipment. Dust and dirt, for example, can accumulate on sensitive components and interfere with their operation. Fluids and liquids can cause short circuits and corrosion, while bacteria and germs can lead to infections and cross-contamination.

Effects of contaminants

The presence of contaminants can have a range of negative effects on medical equipment, including:

- Reduced accuracy

- Increased risk of malfunction

- Shortened lifespan

- Compromised safety

These effects can compromise the quality of patient care and put both patients and healthcare providers at risk. It is therefore essential to take proactive measures to prevent and remove contaminants from medical equipment.

Prevention and mitigation strategies

There are several strategies that can help prevent and mitigate the impact of contaminants on medical equipment, including:

- Regular cleaning and maintenance

- Use of protective covers and barriers

- Proper storage and handling

- Implementation of infection control protocols

By implementing these strategies, healthcare facilities can ensure that their medical equipment remains in optimal condition and continues to deliver accurate and reliable results.

Conclusion

Contaminants can have a significant impact on the performance of medical equipment, leading to potential errors in diagnosis and treatment. It is essential for healthcare facilities to take proactive measures to prevent and mitigate the effects of contaminants on medical devices. By implementing regular cleaning and maintenance, using protective covers, and following infection control protocols, healthcare providers can ensure that their equipment remains in optimal condition and continues to deliver high-quality care to patients.

#contaminants #medical equipment #impact #prevention #maintenance #infection control #accuracy

frazy kluczowe:

– Impact of contaminants on medical equipment performance

– Strategies for preventing contaminants in medical equipment

– Effects of contaminants on healthcare facilities

– Importance of maintaining clean medical equipment

Case studies of improved patient satisfaction with laser-cleaned medical equipment

Here are some case studies that demonstrate the impact of laser-cleaned medical equipment on patient satisfaction:

1. Hospital A implemented laser cleaning technology for their surgical instruments. Patients reported a significant decrease in post-operative infections, leading to higher satisfaction rates among patients and their families.

2. Clinic B used laser cleaning for their endoscopes, resulting in clearer images and more accurate diagnoses. Patients were impressed by the improved quality of care and expressed higher levels of satisfaction with their overall experience.

3. Medical Center C adopted laser cleaning for their dental equipment, leading to a reduction in cross-contamination and improved oral health outcomes. Patients were pleased with the cleanliness of the equipment and reported feeling more confident in the care they received.

Overall, these case studies highlight the positive impact of laser-cleaned medical equipment on patient satisfaction. By investing in this technology, healthcare facilities can improve patient outcomes and enhance the overall patient experience.

#laser #cleaning #medical #equipment #patient #satisfaction

frazy kluczowe:

– laser cleaning technology in healthcare

– improved patient outcomes with laser-cleaned equipment

– impact of clean medical equipment on patient satisfaction

Comparison of laser cleaning with traditional cleaning methods

Laser cleaning is a non-contact, non-abrasive method that uses high-intensity laser beams to remove contaminants from surfaces. The process involves focusing the laser beam on the surface to be cleaned, which causes the contaminants to vaporize and be removed without damaging the underlying material. This method is particularly effective for delicate surfaces or hard-to-reach areas.

On the other hand, traditional cleaning methods often involve the use of harsh chemicals or abrasive materials, which can be harmful to both the environment and the workers performing the cleaning. In addition, these methods can be time-consuming and labor-intensive, leading to increased costs and downtime.

Benefits of laser cleaning:

– Environmentally friendly: Laser cleaning does not produce any waste or harmful emissions, making it a more sustainable option.

– Precision: Laser cleaning can be controlled with high precision, allowing for targeted cleaning without damaging the surface.

– Efficiency: Laser cleaning is faster and more efficient than traditional methods, reducing downtime and labor costs.

– Safety: Laser cleaning eliminates the need for harsh chemicals or abrasive materials, creating a safer work environment for workers.

Drawbacks of traditional cleaning methods:

– Environmental impact: Traditional cleaning methods can produce harmful emissions and waste, contributing to pollution.

– Labor-intensive: Traditional cleaning methods often require manual labor and can be time-consuming.

– Damage to surfaces: Harsh chemicals or abrasive materials used in traditional cleaning methods can damage surfaces.

In conclusion, laser cleaning offers a more efficient, environmentally friendly, and precise alternative to traditional cleaning methods. While traditional methods may still be necessary in some cases, the benefits of laser cleaning make it a compelling option for industries looking to improve their cleaning processes.

#laser #cleaning #traditional #methods #environmentallyfriendly #efficiency #precision #safety

frazy kluczowe:

– Laser cleaning vs traditional methods

– Benefits of laser cleaning

– Drawbacks of traditional cleaning

– Environmentally friendly cleaning

– Precision cleaning techniques

- Laser cleaning for removing contaminants from rubber surfaces - 3 August 2024

- Laser cleaning for removing contaminants from medical equipment - 23 April 2024

- How to use Error 404 - 23 April 2024